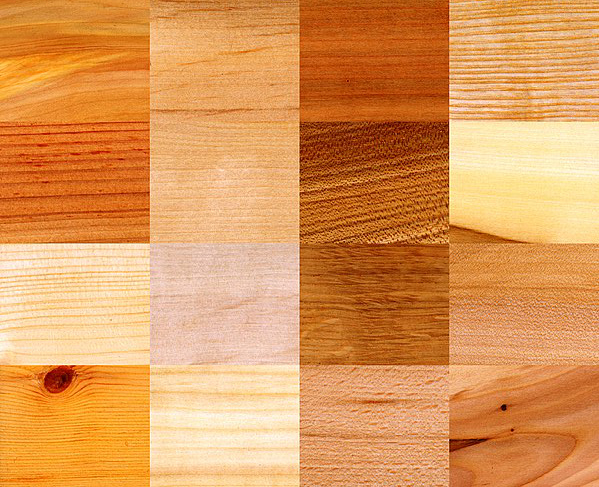

Types of Materials

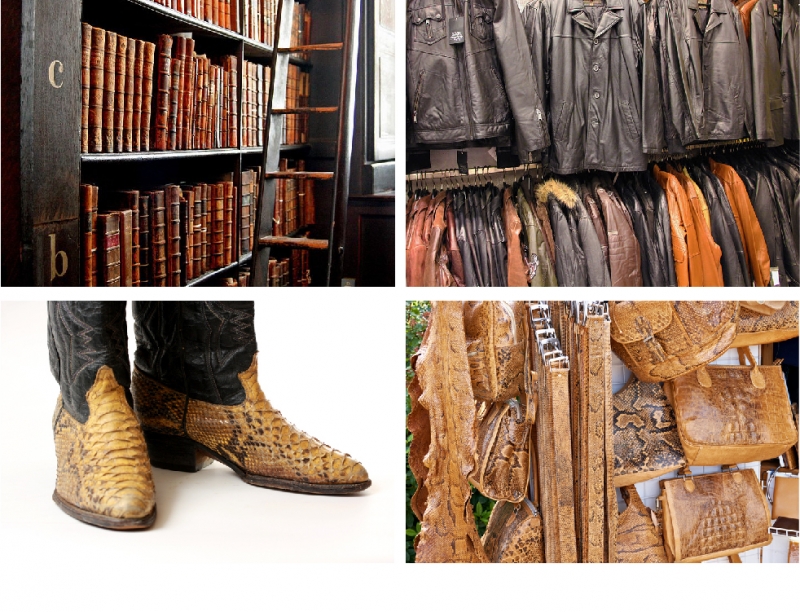

Objects made of different materials (various sources, see article)

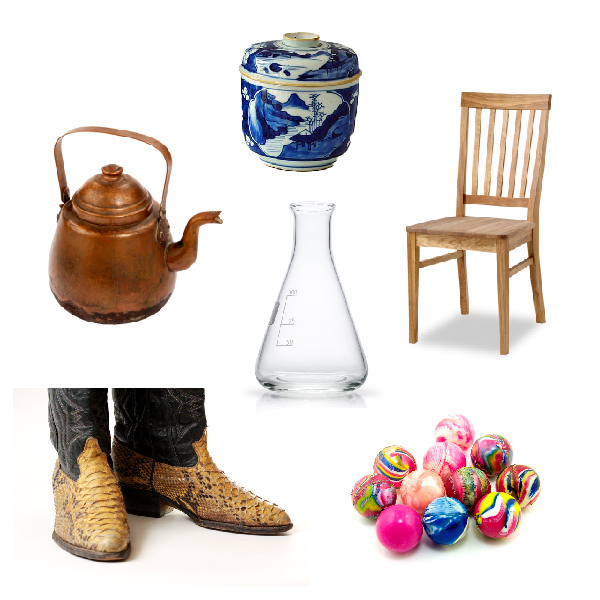

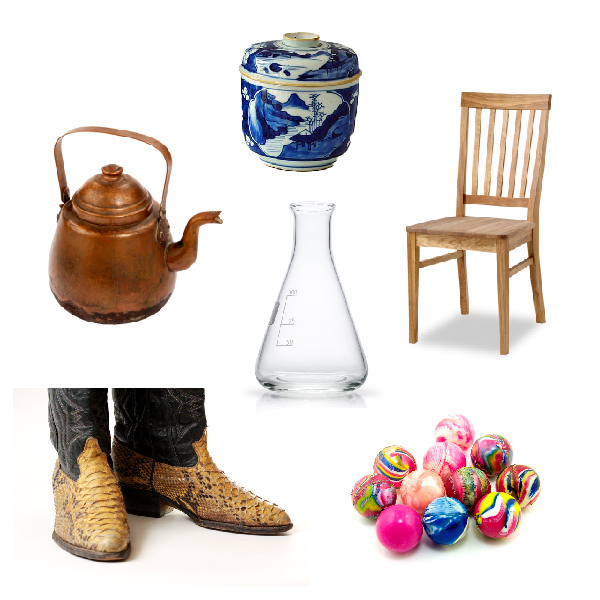

Objects made of different materials (various sources, see article)

7.7

How does this align with my curriculum?

BC

2

Science Grade 2 (June 2016)

Big Idea: Materials can be changed through physical and chemical processes.

BC

K

Science K (June 2016)

Big Idea: Humans interact with matter every day through familiar materials.

NU

1

K-6 Science and Technology Curriculum (NWT, 2004)

Matter and Materials: Characteristics of Objects and Properties of Materials

NU

5

K-6 Science and Technology Curriculum (NWT, 2004)

Matter and Materials: Properties of and Changes in Matter

ON

K

The Kindergarten Program (2016)

13. use the processes and skills of an inquiry stance (i.e., questioning, planning, predicting, observing, and communicating)

PE

K

Science K (June 2016)

Big Idea: Humans interact with matter every day through familiar materials.

YT

2

Science Grade 2 (British Columbia, June 2016)

Big Idea: Materials can be changed through physical and chemical processes.

NT

1

K-6 Science and Technology Curriculum (NWT, 2004)

Matter and Materials: Characteristics of Objects and Properties of Materials