Rebecca Smith

About me

I was born/grew up in: Belleville, Ontario, Canada

I now live in: Kingston, Ontario, Canada

I completed my training/education at:

Manufacturing and Mechanical Engineering – Loyalist College, Belleville, Ontario 2018

Business – Trenval, Loyalist College, Belleville, Ontario 2015

Welding – Canadian Welding Skills, Ennismoore, Ontario 2014

Welding – Lakeland College, Vermillion, Alberta 2012

Automotive power – Loyalist College, Belleville, Ontario 2006

What I do at work

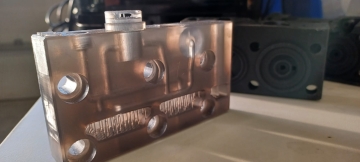

work for a company that does custom construction and machining as well as engineered drawings for a large client base. Most of the work we do is for the food and health industries. We build things like stainless steel and aluminum conveyors or large holding tanks for food and liquids.

Each day I can be building something different from what I was working on the day before. It’s one of the things I love about my career; the variety of work I get to do never gets boring. There are many things about my job that are still new and exciting to learn. This gives me the chance to always be advancing in my career. I love being challenged and solving problems. And when the product finally comes together and I get to see the customers happy that is always rewarding for me.

I use the knowledge I’ve gained from school as well as the courses daily to help me be the best I can when working on a project. For example, I use my knowledge of the chemistry of metals every time I weld. The connections I’ve made with my classmates and teachers will last a life time and are a great support group when needed.

My career path is

The path to my career is kind of a long one. When I was in high school I wanted to be an automotive technician and I even went to college for a year. Later I moved to Alberta to pursue my career in automotive but after years of not being able to find a good shop to work and finish my schooling I decided to change careers. As life would have it I found work in a welding shop and fell in love with welding and fabrication. Since then I have advanced my knowledge in welding and even moving into machining to become more adaptable in my work.

There have been many winding roads I have taken to get where I am today and I wouldn’t change any of it. The paths I have taken have made me who I am and allowed me to meet a lot of great people. And at the end of the day I do something I love every day.

My path has lead me to become a mentor to my fellow students and people I meet in everyday life. By doing so I have come to realize that because I love welding and fabricating so much I want to pass on my knowledge. I hope to become a teacher someday and hopefully encourage young people to be part of the trades’ community.

I am motivated by

I get satisfaction from seeing happy customers at the end of the day. It is great knowing I created something that is helping a company or making someone’s everyday life easier and or safer. A big motivation for me as well is being able to share my stories and experiences with others and young people who are interested in my trade. I love being that “go to person” for the times you need a pick me up or if you’re doubting yourself at school or on the job. I enjoy knowing my personal experiences with welding and fabrication can help motivate others to keep pushing in their own careers or to look for one that makes them happy.

How I affect peoples’ lives

Because we make so many things for the public our products effect the public quite a bit. We need to ensure our metal and welds are food grade approved and up to government standards. Some of the companies we work with have to have some kind of certification stamped on the product. For example, when we make something that’s going to be used with food we need to make sure we are using food grade stainless steel. We also have to make sure we have sound welds to make sure there are no contamination to the products.

Outside of work I

My favorite activities to do outside of work are mostly spending time with my family. I love spending the nice days outside with my spouse and our dogs hiking and going to the beach in the summer. As a hobby, I enjoy creating new items from scrap metal and old horse shoes. Lastly when I’m not working or just relaxing with my loved ones I try and get out to as many events as I can that will encourage youth and woman of today to think about a career in the trades by sharing my experiences.

My advice to others

If you do something you love you will never work a day in your life! From my own personal experience, I can say if you want it bad enough nothing can stop you or hold you back. Find something you love to do by getting out there and explore every option possible. And when you find the one you love doing go for it.

- Art

- Drama

- Geography

- Home Economics/Family Studies

- Industrial Arts/Shop Programs

- Music

- Physical Education/Health

- Science

- Technology

- Brought people together

- Enjoyed doing things on my own

- Always wanted to be outside

- Liked helping people

- Organized activities for my friends

- Played on a sports team

- Enjoyed working with my hands

- Wanted to be in charge

- Liked being given specific instructions

- Liked being given free range to explore my ideas

- Engaged in volunteer activities

- Felt at home in the outside, natural environment

Related Topics

Partners

Lets Talk Science is grateful to Skills Canada Ontario for connecting us with this individual.