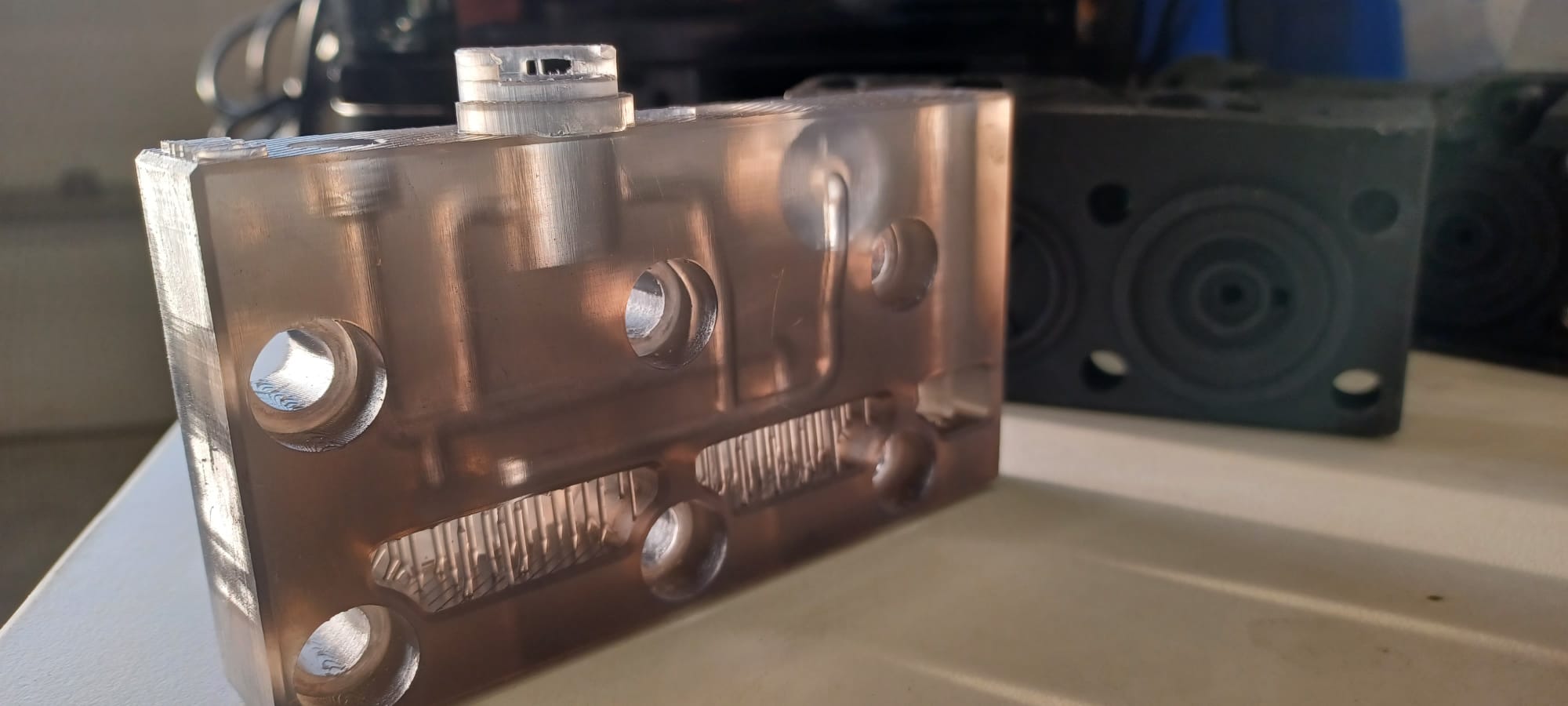

A 3D printed manifold, designed and printed by Scott Baker. The manifold has channels to carry water between different valves which will be plugged into the manifold. A part like this would be very difficult and expensive to produce using other manufacturing processes.

Scott Baker

Mechanical Designer

GeologicAI

Learn About My Career

I design physical parts and small machines and I create prototypes that we can quickly test.

I was born/grew up in: Peterborough, Ontario.

I now live in: Calgary, Alberta.

I completed my training/education at:

BScH Geological Sciences, Queen's University, Mechanical Engineering Technology, Southern Alberta Institute of Technology.

I design physical parts and small machines. I use three-dimensional (3D) software to do this. I spend about 70% of my time working at the computer. The other 30% of my time is used in constructing, assembling, and testing those machines. We call these machines prototypes. By testing them, we figure out what works and what doesn't. We make mistakes, learn, and repeat until it works.

For simple projects, the things I design usually work on the first try. For more complex problems, or more complex machines, I might spend months testing different prototypes. This helps me figure out what DOESN’T work, and what DOES work.

I have experience with mechanical, electrical, and automated systems. I got this by working on a lot of different design projects. I use my experience to try to design things that will work the first time. If they don’t work the first time, I want them to fail in a way that will help us learn a lot, quickly. That way we can easily adapt for another attempt.

When I design a finished product, I try to make sure it is easy for someone to learn, operate, and maintain. This job needs both creative and critical thinking. I’m usually trying to find a new and better way of doing something. I also need to be able to critique my own design.

It helps to be curious. I've worked with biologists, chemists, and doctors. I’ve also worked with environmental monitoring, remote sensing drone companies, as well as drilling and mining companies. Even though I have no expertise in what they do, I’m engaged, and I ask good questions. This helps us work together to build the solution that they need.

Sometimes I work with a team. Sometimes I work solo. Either way, communication is important when starting any project. I make sure that what I design will solve the problem that my client, or my boss, has. I haven’t used a lot of math in my job so far. But I think I will need to refresh my math and programming skills to advance in my career. I will need to be able to tackle more complex and interesting problems.

We use a lot of 3D printers, CNC machining equipment, laser cutters, water jet cutters, welding equipment, carpentry and hand tools. We also use a variety of software. For me, these are usually Solidworks, Camworks, or Fusion360.

After high school, I enrolled in the Geologic Sciences program at Queen's University. I enjoyed most of the classes, but I didn't feel inspired by the types of jobs I was seeing. I still had a tiny view of the world at this time in my life.

While working a summer job with my professor, I stumbled onto a magazine about quadcopter drones. I thought, "I want to design things like that." After university, I worked odd jobs for a couple of years. Then I enrolled in the Mechanical Engineering Tech diploma program at Southern Alberta Institute of Technology. While there, I got a summer job in SAIT’s Applied Research and Innovation Services program. This program engages students in real-world industry research projects. Through this program, outside organizations can have specialized technology created to solve their needs. Once the project is developed, student researchers work to solve the problem, or create new technology. I worked for them for another four years after graduating. The rest is history.

I enjoy creativity and design. But I’m also very practical and analytical. I’ve enjoy this work. And I feel I’m good at it. In the future, I think my career will slowly change as I continue learning. Especially as I learn what I care about most. Whether I keep working for industry, or return to government research and development, or go back to school for a master's or PhD someday, I think my work will always involve critical and creative thinking.

I often work in the middle. Scientists and inventors identify problems in the world. I help them apply a solution. Then that solution is used by companies or governments to make change. On a smaller scale, if any of my friends need something designed or fixed, they come to me!

I moved to Calgary for the mountains. I do a lot of rock climbing, on big mountains and small overhanging cliffs. I go on remote backpacking trips in the summer months. I explore the enormous and wild caves of the Rocky Mountains. I backcountry ski in the winter and climb indoors.

I'm always designing something. This includes such things as small 3D printed widgets to solve problems around the house. Or it might be a specialized tool for cave exploration, and my indoor climbing wall! I also love board games. And I have a soft spot for old console video games.

Try out as many things as you can before you commit. Find out what really gets you going, and the people you really connect with.

What I do at work

I design physical parts and small machines. I use three-dimensional (3D) software to do this. I spend about 70% of my time working at the computer. The other 30% of my time is used in constructing, assembling, and testing those machines. We call these machines prototypes. By testing them, we figure out what works and what doesn't. We make mistakes, learn, and repeat until it works.

For simple projects, the things I design usually work on the first try. For more complex problems, or more complex machines, I might spend months testing different prototypes. This helps me figure out what DOESN’T work, and what DOES work.

I have experience with mechanical, electrical, and automated systems. I got this by working on a lot of different design projects. I use my experience to try to design things that will work the first time. If they don’t work the first time, I want them to fail in a way that will help us learn a lot, quickly. That way we can easily adapt for another attempt.

When I design a finished product, I try to make sure it is easy for someone to learn, operate, and maintain. This job needs both creative and critical thinking. I’m usually trying to find a new and better way of doing something. I also need to be able to critique my own design.

It helps to be curious. I've worked with biologists, chemists, and doctors. I’ve also worked with environmental monitoring, remote sensing drone companies, as well as drilling and mining companies. Even though I have no expertise in what they do, I’m engaged, and I ask good questions. This helps us work together to build the solution that they need.

Sometimes I work with a team. Sometimes I work solo. Either way, communication is important when starting any project. I make sure that what I design will solve the problem that my client, or my boss, has. I haven’t used a lot of math in my job so far. But I think I will need to refresh my math and programming skills to advance in my career. I will need to be able to tackle more complex and interesting problems.

We use a lot of 3D printers, CNC machining equipment, laser cutters, water jet cutters, welding equipment, carpentry and hand tools. We also use a variety of software. For me, these are usually Solidworks, Camworks, or Fusion360.

My career path is

After high school, I enrolled in the Geologic Sciences program at Queen's University. I enjoyed most of the classes, but I didn't feel inspired by the types of jobs I was seeing. I still had a tiny view of the world at this time in my life.

While working a summer job with my professor, I stumbled onto a magazine about quadcopter drones. I thought, "I want to design things like that." After university, I worked odd jobs for a couple of years. Then I enrolled in the Mechanical Engineering Tech diploma program at Southern Alberta Institute of Technology. While there, I got a summer job in SAIT’s Applied Research and Innovation Services program. This program engages students in real-world industry research projects. Through this program, outside organizations can have specialized technology created to solve their needs. Once the project is developed, student researchers work to solve the problem, or create new technology. I worked for them for another four years after graduating. The rest is history.

I am motivated by

I enjoy creativity and design. But I’m also very practical and analytical. I’ve enjoy this work. And I feel I’m good at it. In the future, I think my career will slowly change as I continue learning. Especially as I learn what I care about most. Whether I keep working for industry, or return to government research and development, or go back to school for a master's or PhD someday, I think my work will always involve critical and creative thinking.

How I affect peoples’ lives

I often work in the middle. Scientists and inventors identify problems in the world. I help them apply a solution. Then that solution is used by companies or governments to make change. On a smaller scale, if any of my friends need something designed or fixed, they come to me!

Outside of work I

I moved to Calgary for the mountains. I do a lot of rock climbing, on big mountains and small overhanging cliffs. I go on remote backpacking trips in the summer months. I explore the enormous and wild caves of the Rocky Mountains. I backcountry ski in the winter and climb indoors.

I'm always designing something. This includes such things as small 3D printed widgets to solve problems around the house. Or it might be a specialized tool for cave exploration, and my indoor climbing wall! I also love board games. And I have a soft spot for old console video games.

My advice to others

Try out as many things as you can before you commit. Find out what really gets you going, and the people you really connect with.

When I was a student I enjoyed:

- Math

- Physical Education/Health

- Science

- Technology

When I was a student, I would describe myself as someone who:

- Liked reading

- Played video games

- Felt great satisfaction in getting good grades

- Wasn't sure what I wanted to do

- Liked to take things apart to see how they worked

- Liked to design or build things

- Learned best by doing

- Had no close friends

- Was not good at communicating

Related Topics

Explore More Career Profiles

-

Brianna Lummerding

Career Profiles

Agronomic Innovation Manager

I look after all things related to soil management for a group of retailers. -

Li Tan (he/him)

Career Profiles

Molecular Lead

I coordinate the day-to-day operations in the DNA Extraction Lab. -

Tyler Morhart (video)

Career Profiles

Scientist, Beamline Responsible - SyLMAND

I am responsible for the SyLMAND beamline at the Canadian Light Source synchrotron facility. -

Li Tan (Video)

Career Profiles

Molecular Lead

I coordinate the day-to-day operations in the DNA Extraction Lab. -

Rashell Featherstone (she/her)

Career Profiles

Senior Program Associate

I coordinate projects for the development of new products at STEMCELL. -

Kira Hoffman (she/her)

Career Profiles

Postdoctoral Researcher/Fire Ecologist

I am a researcher at both a university and a not-for profit organization where I am gaining experience to become a senior researcher. -

Zoë Ehlert (Video)

Career Profiles

Manager, Marker Assisted Breeding

I lead a team that develops canola crops by breeding plants with traits we are looking for. -

Zoë Ehlert

Career Profiles

Manager, Marker Assisted Breeding

I lead a team that develops canola crops by breeding plants with traits we are looking for. -

Jennifer Baltzer (she/her)

Career Profiles

Professor and Canada Research Chair in Forests and Global Change

I work at a university, teaching students and conducting research on the impact of climate change on forests in Canada and around the world. -

Caitlyn Lyons (she/her)

Career Profiles

Ph.D. Candidate

I am working towards my PhD and studying the forests in the Northwest Territories. -

Joann Whalen

Career Profiles

Professor at the Faculty of Agricultural and Environmental Sciences,

I teach advanced courses on how to manage soils to produce healthy, nutritious food and maintain healthy ecosystem functions.