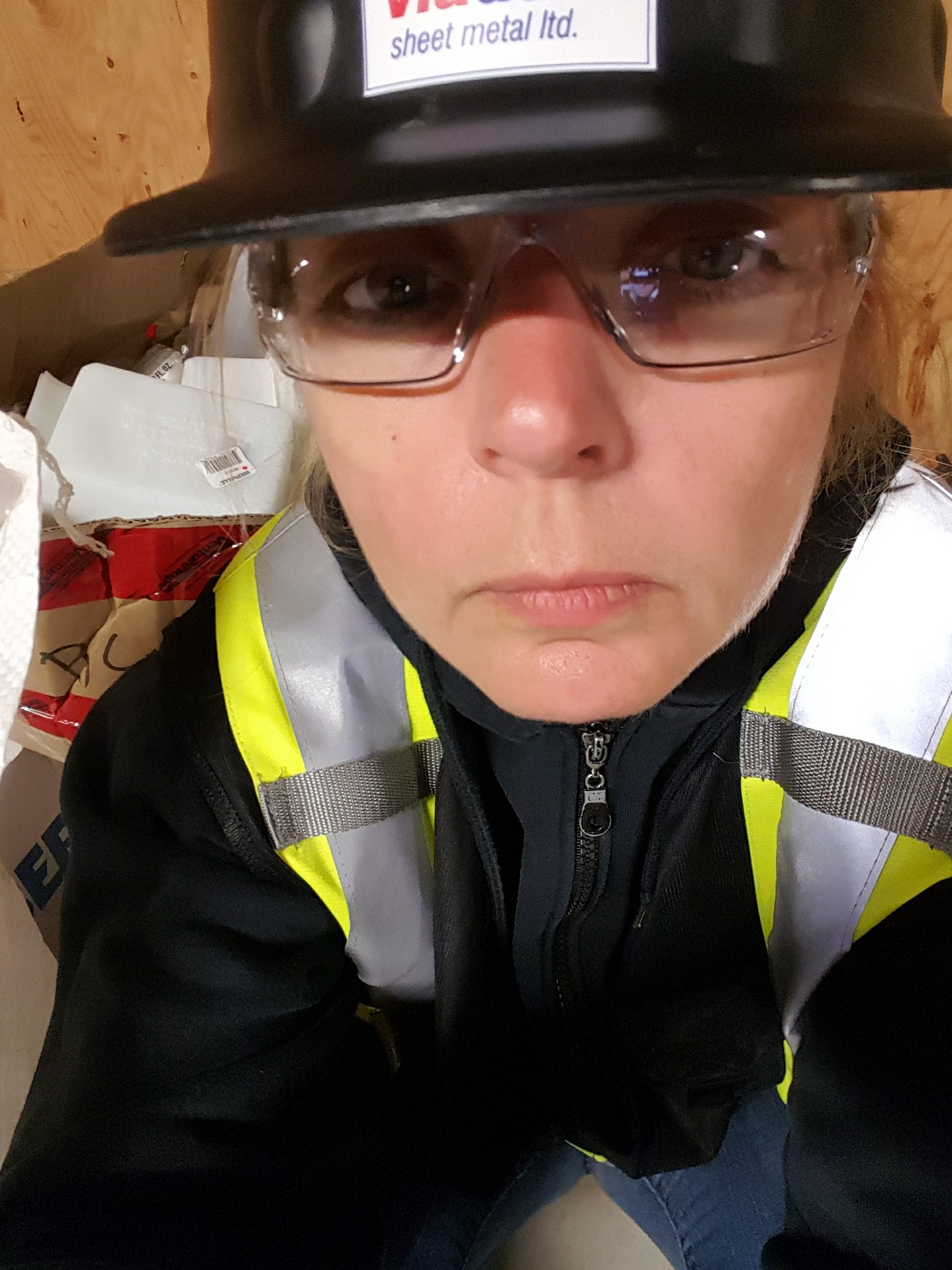

Sheila Sadler

Sheet Metal Journeyperson

Viaduct Sheet Metal

Learn About My Career

Sheila Sadler is a Sheet Metal Journeyperson for Viaduct Sheet Metal.

I was born/grew up in: Vancouver, BC

I now live in: Vancouver, BC

I completed my training/education at: Local 280 Sheet metal worker training center

I am a sheet metal Journeyperson. Sheet metal is metal that comes in thin, flat sheets. The sheets come in different sizes and sometimes in rolls. Sheet metal comes in different thicknesses depending on what it will be used for. The sheet metal that I work with is not very thick as it is used to make pipes that are part of building air conditioning and circulation systems. Some sheet metal is thick enough that it is used to construct buildings such as metal, industrial buildings.

There are two different sides to the sheet metal trade; field and shop. In the shop, we make the metal fittings and parts that will be used in the field (i.e., on the job site). We make these items by cutting them on a machine and then we run the cut pieces thru other machines. These machines add bends to create the metal product needed. In the field, other sheet metal workers take what we have built in the shops and install it in the building.

There is sheet metal in all buildings. It is in the air conditioning or air circulation systems. The ducts and pipes that move moves air around a house or workplace are all made from sheet metal. Sheet metal workers sometimes do welding as well. We also have to be able to do ladder work, some lifting, and use hand tools. In this trade there is a lot of teamwork involved. As a Journeyperson, I work with apprentices who are learning to become sheet metal workers.

I married and had kids right out of high school. I thought I would be a stay at home mom and wife forever. Well that changed and I moved out with my two little girls and started working at low paying jobs. I realized I wouldn't be able to give them a stable life this way. I had been married to a plumber and had helped him at times. So, I thought why couldn't I do that.

I went to a trades sampling program and choose heavy fab (which is building metal items by cutting, bending and joining part together). After I finished my classes, I could not find work in this area. So I went back to being a waitress. One day, while I was at work, a guy came in and I had a few minutes to chat so I asked what he did. We started taking about metal and he asked why I knew so much. I explained what happened and he smiled collected his lunch and went on with his day. About an hour later he came back and gave me information about a job opening. He had also made an appointment with the apprentice coordinator for me. I saw her the next day and I went to my first sheet metal job. I worked there for a while before joining the company I work with now. I’ve worked here for 17 years now. That stranger gave me the gift of an opportunity to prove myself. I am thankful everyday.

I love to see the end results – something you look at and see what you made. It is a crazy sense of pride when you make something. I still go by buildings and say, “I worked on that!” I have made things that were used in movies. Working in this industry has allowed me to raise my kids by myself and they had a good life. I also like welding as I find it peaceful and relaxing.

The work I do helps create the system that brings warm and cool air into the places were people live and work. This makes their living and work places more comfortable and healthier.

I like to be outside in nature and like fishing and camping (tent camping lol). I also enjoy crochet and cooking. I also enjoy talking to people about the job I do.

This is a good solid job. You will make good money and you can accomplish a lot with this trade.

What I do at work

I am a sheet metal Journeyperson. Sheet metal is metal that comes in thin, flat sheets. The sheets come in different sizes and sometimes in rolls. Sheet metal comes in different thicknesses depending on what it will be used for. The sheet metal that I work with is not very thick as it is used to make pipes that are part of building air conditioning and circulation systems. Some sheet metal is thick enough that it is used to construct buildings such as metal, industrial buildings.

There are two different sides to the sheet metal trade; field and shop. In the shop, we make the metal fittings and parts that will be used in the field (i.e., on the job site). We make these items by cutting them on a machine and then we run the cut pieces thru other machines. These machines add bends to create the metal product needed. In the field, other sheet metal workers take what we have built in the shops and install it in the building.

There is sheet metal in all buildings. It is in the air conditioning or air circulation systems. The ducts and pipes that move moves air around a house or workplace are all made from sheet metal. Sheet metal workers sometimes do welding as well. We also have to be able to do ladder work, some lifting, and use hand tools. In this trade there is a lot of teamwork involved. As a Journeyperson, I work with apprentices who are learning to become sheet metal workers.

My career path is

I married and had kids right out of high school. I thought I would be a stay at home mom and wife forever. Well that changed and I moved out with my two little girls and started working at low paying jobs. I realized I wouldn't be able to give them a stable life this way. I had been married to a plumber and had helped him at times. So, I thought why couldn't I do that.

I went to a trades sampling program and choose heavy fab (which is building metal items by cutting, bending and joining part together). After I finished my classes, I could not find work in this area. So I went back to being a waitress. One day, while I was at work, a guy came in and I had a few minutes to chat so I asked what he did. We started taking about metal and he asked why I knew so much. I explained what happened and he smiled collected his lunch and went on with his day. About an hour later he came back and gave me information about a job opening. He had also made an appointment with the apprentice coordinator for me. I saw her the next day and I went to my first sheet metal job. I worked there for a while before joining the company I work with now. I’ve worked here for 17 years now. That stranger gave me the gift of an opportunity to prove myself. I am thankful everyday.

I am motivated by

I love to see the end results – something you look at and see what you made. It is a crazy sense of pride when you make something. I still go by buildings and say, “I worked on that!” I have made things that were used in movies. Working in this industry has allowed me to raise my kids by myself and they had a good life. I also like welding as I find it peaceful and relaxing.

How I affect peoples’ lives

The work I do helps create the system that brings warm and cool air into the places were people live and work. This makes their living and work places more comfortable and healthier.

Outside of work I

I like to be outside in nature and like fishing and camping (tent camping lol). I also enjoy crochet and cooking. I also enjoy talking to people about the job I do.

My advice to others

This is a good solid job. You will make good money and you can accomplish a lot with this trade.

When I was a student I enjoyed:

- Foods and Nutrition

- Home Economics

- Technology

When I was a student, I would describe myself as someone who:

- Enjoyed doing things on my own

- Enjoyed working with my hands

- Liked being given free range to explore my ideas

- Never wanted to be in the classroom

- Always threw the best parties

- Didn't really care about grades

- Wasn't sure what I wanted to do

- Went to Alternative Schools

Related Topics

Explore More Career Profiles

-

Brianna Lummerding

Career Profiles

Agronomic Innovation Manager

I look after all things related to soil management for a group of retailers. -

Li Tan (he/him)

Career Profiles

Molecular Lead

I coordinate the day-to-day operations in the DNA Extraction Lab. -

Tyler Morhart (video)

Career Profiles

Scientist, Beamline Responsible - SyLMAND

I am responsible for the SyLMAND beamline at the Canadian Light Source synchrotron facility. -

Li Tan (Video)

Career Profiles

Molecular Lead

I coordinate the day-to-day operations in the DNA Extraction Lab. -

Rashell Featherstone (she/her)

Career Profiles

Senior Program Associate

I coordinate projects for the development of new products at STEMCELL. -

Kira Hoffman (she/her)

Career Profiles

Postdoctoral Researcher/Fire Ecologist

I am a researcher at both a university and a not-for profit organization where I am gaining experience to become a senior researcher. -

Zoë Ehlert (Video)

Career Profiles

Manager, Marker Assisted Breeding

I lead a team that develops canola crops by breeding plants with traits we are looking for. -

Zoë Ehlert

Career Profiles

Manager, Marker Assisted Breeding

I lead a team that develops canola crops by breeding plants with traits we are looking for. -

Jennifer Baltzer (she/her)

Career Profiles

Professor and Canada Research Chair in Forests and Global Change

I work at a university, teaching students and conducting research on the impact of climate change on forests in Canada and around the world. -

Caitlyn Lyons (she/her)

Career Profiles

Ph.D. Candidate

I am working towards my PhD and studying the forests in the Northwest Territories. -

Joann Whalen

Career Profiles

Professor at the Faculty of Agricultural and Environmental Sciences,

I teach advanced courses on how to manage soils to produce healthy, nutritious food and maintain healthy ecosystem functions.