How is oil moved from one place to another?

Train oil cars (Dragunov1981, iStockphoto)

Train oil cars (Dragunov1981, iStockphoto)

How does this align with my curriculum?

| Grade | Course | Topic |

|---|

This backgrounder explains the four main ways that oil is moved over land and water.

For thousands of years, people have extracted crude oil from under the Earth. For over 150 years in Canada, we have used crude oil to power our modern way of life. Crude oil is also known as petroleum. Today, petroleum is used to help make all kinds of things. For example, petroleum is used to make plastic, candles, crayons, lipstick, Aspirin and solar panels.

But can you guess what the most common use of petroleum is? If you said making fuel, you’re right! Petroleum is used to make fuel for cars, airplanes, and industrial machinery. Every day, nearly 100 million barrels of crude oil is moved from deep below the Earth to more than a billion fuel tanks around the world. Let’s look at the four ways crude oil is moved.

Did you know?

The unit of measurement for crude oil is a barrel. The unit was adopted in 19th century Pennsylvania when oil producers wanted to make the sale of crude oil more standardized. They chose to sell their oil in English wine barrels, which held 42 gallons (159 litres), and the unit has been used ever since to measure crude oil.

How do pipelines move oil?

Pipelines are the main way that crude and refined oil gets moved. Pipelines can move oil hundreds, and sometimes even thousands, of kilometres to the places where it’s used. The most often used pipelines are up to a metre wide and made of steel or plastic. They can snake across entire continents! So how does the oil actually travel through these tubes?

There are three types of pipes in a petroleum pipeline network.

- Gathering pipelines carry oil from the wells to storage facilities or processing plants.

- Feeder pipelines move the oil from storage facilities and processing plants to the transmission pipelines.

- Transmission pipelines are responsible for moving oil from its source to various markets across the country.

Pumps at the source and all the way to the final destination keep oil moving through the entire pipeline. On average, oil moves at speeds between 5 km/h and 10 km/h. To protect them from rust, steel pipelines may be reinforced with wood slats, concrete coatings, or polyethylene. Polyethylene is the stuff used to make plastic bottles.

It’s important to make sure debris and waste material don’t build up in the pipes. That’s why oil companies regularly send special scrapers known as ‘pigs’ or ‘go devils’ down lengths of pipeline. Pigs have been used as far back as the 1870s. Back then, they were little more than a wire-wrapped bundle of straw. They were inserted in one end of a pipeline and retrieved at the other. Today, oil companies send ‘smart pigs’ down pipelines. These are sophisticated probes with on-board computers, sensors, and powerful magnets to help collect tiny bits of metal in the pipes.

Pipelines can be above ground or underground. Either way, pipelines are the most efficient way to move oil over land. Pipelines keep moving oil separate from the natural environment. But constructing pipelines often disrupts the surrounding ecosystems. For example, people might remove trees, clear topsoil, and dig trenches to accommodate the pipes.

If pipelines get damaged, they can leak. Leaks, too, can disrupt an ecosystem. Pipes can get damaged because of design flaws, sabotage, or wear and tear as the pipes age.

How do ships move oil?

Oil can also be transported over water. Oil has been shipped over water since the late 1800s. Back then, 55-metre long ships carried up to 250 tonnes of crude oil between ports. Today, oil is shipped on 415-metre long Ultra-Large Crude Carriers (ULCCs). They can weigh up to half-a-million tonnes when fully loaded. They can transport more than 2 million barrels of oil per trip.

Double-hulled crude tankers move crude oil from near the source of the oil to refineries near seaports. Smaller product tankers move oil from refineries to destinations near where it will be used. For example, product tankers might move oil to destinations near train tracks. Or, product tankers might move oil to storage facilities serviced by tank trucks bound for gas stations.

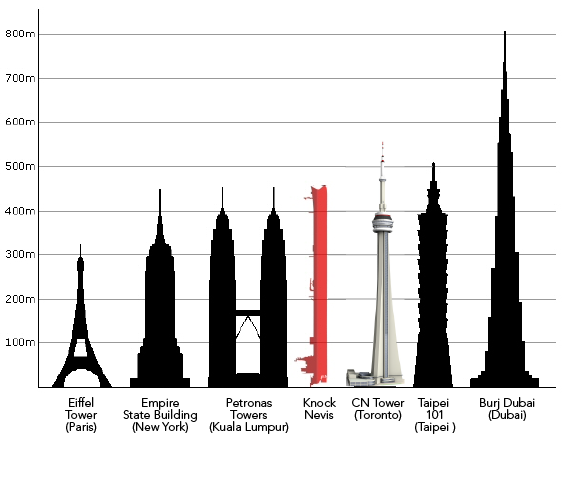

Tanker ships are the most efficient way to move oil great distances across water. They’re also some of the largest pieces of technology ever built. For example, the oil tanker Seawise Giant (also known as Knock Nevis) was the longest ship ever built and the largest self-propelled object ever made. It was 458 metres long. That’s nearly half a kilometre! Fully loaded, it weighed 657 000 tonnes.

Because of their size, modern oil tankers have made transporting oil much cheaper than it used to be.

In the 1950s, shipping costs made up about 33% of the price of oil transported from the Persian Gulf to the U.S. After the development of supertankers in the 1970s, the cost of shipping along that same route dropped to 5% of the oil’s final commercial price. Since 2010, that cost has been less than 3%. These days, for a ton of crude oil worth $800, the shipping cost is only about $20, or about $0.08 a litre at your local gas station.

Today, 60% of all transported oil is transported by oil tanker. But transporting oil by ships is not without risks. Oil can be spilled from tankers during accidents at sea, or while cargo is being loaded or unloaded. Oil spills from tanker ships happen less often than spills from trains and trucks. But spills at sea tend to be much larger. They can have devastating effects on the environment. A large oil spill at sea or near shore can kill millions of birds, fish, and large sea animals. Also, oil tanker exhaust is a major source of pollution. Oil tankers can also pose a large environmental risk if they are damaged. They can get damaged by collisions, during onboard fires, or while they’re being disassembled after they’re no longer in use.

How do trains move oil?

Since the 1860s, trains have pulled tanker cars carrying oil. Believe it or not, these early tanker cars were made of wood! Between the 1920s and 1950s, modern tanker cars were a popular way to move oil. But by the 1960s, pipelines, ships, and tank trucks became the main ways of transporting oil. By 2012, Canada started using more oil than pipelines could move. So once again, trains were in high demand to move oil across the country.

There are currently about 415 000 tank cars in North America that can carry oil by train.

Since 2018, Canada has been phasing out old tank cars and replacing them with DOT-117 tank cars. Each DOT-117 tank car can hold as much as 675 barrels of oil -- that’s almost 110 000 litres! About 150 000 barrels of oil is shipped from the Alberta oil sands per day by rail. That’s a lot of oil!

Trains have some advantages over pipelines. Pipelines take many years to construct. Also, they only follow fixed routes. However, trains carrying oil can use any train track. Additional tank cars can be added when there is increased demand. But more trains moving oil means more risks. For example, if trains carrying oil crash or derail (leave the tracks), there are risks of spills, explosions, and fire.

In July 2013, an unattended train carrying oil derailed in Lac-Mégantic, Quebec. The train rolled down a hill into the town, causing several large explosions and a huge fire, killing 47 people. With oil transport by train on the rise, people are becoming more concerned with the risks of transporting oil this way.

Spills also occur more on trains than on other forms of land-based oil transport. Of these spills, about half of the oil is spilled during transport. Roughly the other half is spilled during loading or unloading. People are calling upon oil companies, rail authorities, and governments to create more rules and policies to help protect against accidents.

Trains are also designed with safety in mind. For example, the part of the train that connects one car to the other is called a coupler. Modern tank cars have special couplers that prevent the cars from separating in an accident or derailment. In the past, if cars separated, a coupler could puncture the tank car in front or behind them. Modern couplers have eliminated that risk.

How do trucks move oil?

Transport by truck is usually the last step in getting oil to the places where it will be used by people like you and me.

Why do we transport fuel by trucks? Often, trucks are the only way to get fuel directly to gas stations. Imagine how difficult driving would be if you could only get gas right beside a train station, in a shipping port, or out of a pipeline!

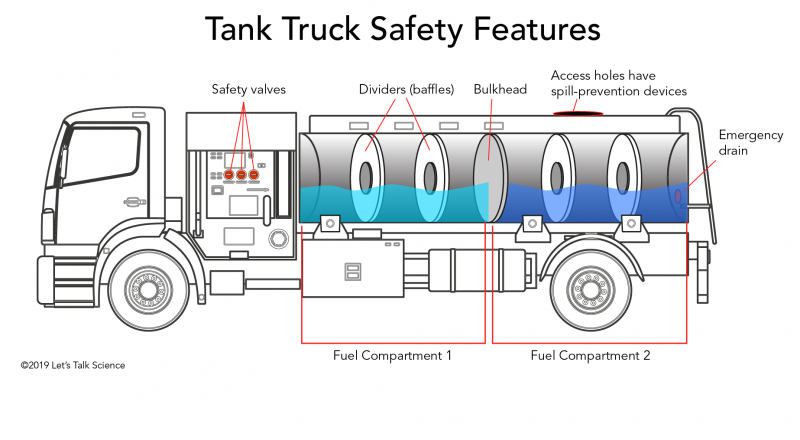

Tank trucks move processed oil, or fuel, in cylinder-shaped containers. These containers look a lot like the tank cars pulled by trains. These trucks can each carry between 10 000 and 45 000 litres of fuel from refineries or storage facilities to the pumps at a gas station.

In tank trucks, the fuel is separated into many compartments. This keeps different grades of fuel separate. That way, trucks can carry all the different kinds of fuel to a service station in one trip.

Tank trucks can carry other types of processed oil, too. They can carry jet fuel to airports. They can also carry propane, furnace oil, and other residential fuels to houses that use them for heating or cooking. Trucks can go anywhere there is a road. That makes them the most convenient way to transport oil products.

Like other forms of oil transport, a drawback to tanker trucks is the possibility of spills during loading or unloading, or in traffic accidents. Driving a tank truck is trickier than most truck loads. That’s because of tank trucks’ high centre of gravity. Think of how much higher the top of the truck is than the driver’s seat. That’s a lot of heavy liquid sloshing around above pretty high up! Because of this, tank trucks can tip over more easily than other kinds of trucks.

Tanker truck spills happen more often than train, ship or pipeline spills. But spills from trucks tend to be smaller compared to other kinds of transports. However, these spills tend to be on roads where many people drive every day.

Summing up...

Every method of transporting petroleum has its benefits. It also has its risks. But one thing is for certain: it would be very hard to power our modern lives without taking these risks!

Learn More

Crude Oil Facts (2018)

Fact sheet from Natural Resources Canada about crude oil extraction, uses, and transport in Canada.

The Different Kinds of Pipelines in Canada

Infographic from the Canadian Energy Pipeline Association describing the types of pipelines in Canada, the type of oil products they move, what they look like, and the size of the network,

Pipelines Transport Billions of Barrels of Petroleum Products Each Year (2014)

A fact sheet from the Association of Oil Pipelines outlining the average cost of transporting petroleum products via pipelines.

Smart Pig Pipeline Inspection (2018)

Video (2:29 min.) from Dominion Energy that includes an explanation about how smart pigging works, as well as a demonstration and animated examples.

References

About Pipelines. (2016). How do pipelines work? Canadian Energy Pipeline Association.

Clear Seas. (n.d.). Oil tankers in Canadian waters.

Conca, J. (2014, April 26). Pick your poison for crude -- Pipeline, rail, truck or boat. Forbes.

Connolly, A. (2018, September 19). Most dangerous rail tank cars to be off Canadian tracks sooner with new timelines: Garneau. Global News.

Gosselin, E. (2013, November 14). Oil tanker spills: An FAQ. The Science Creative Quarterly.

Green, K. P., & Jackson, T. (n.d.). Pipelines are the safest way to transport oil and gas. Fraser Institute.

Hygenic Pigging Systems. (2016, August 24). Scrapers, moles, cleaners and go devils.

Matthews, I. (2018, October 19). How much oil can a rail car transport? Partisan Issues.

Pees, S. T. (2004). Tank cars. Petroleum History Institute.

Tonder, R. V. (2018, November 19). How much gas does a tanker truck hold? Transcourt.

Truck Driving Jobs. (n.d.). The specialized field of driving petroleum tankers.