Mines and Mining

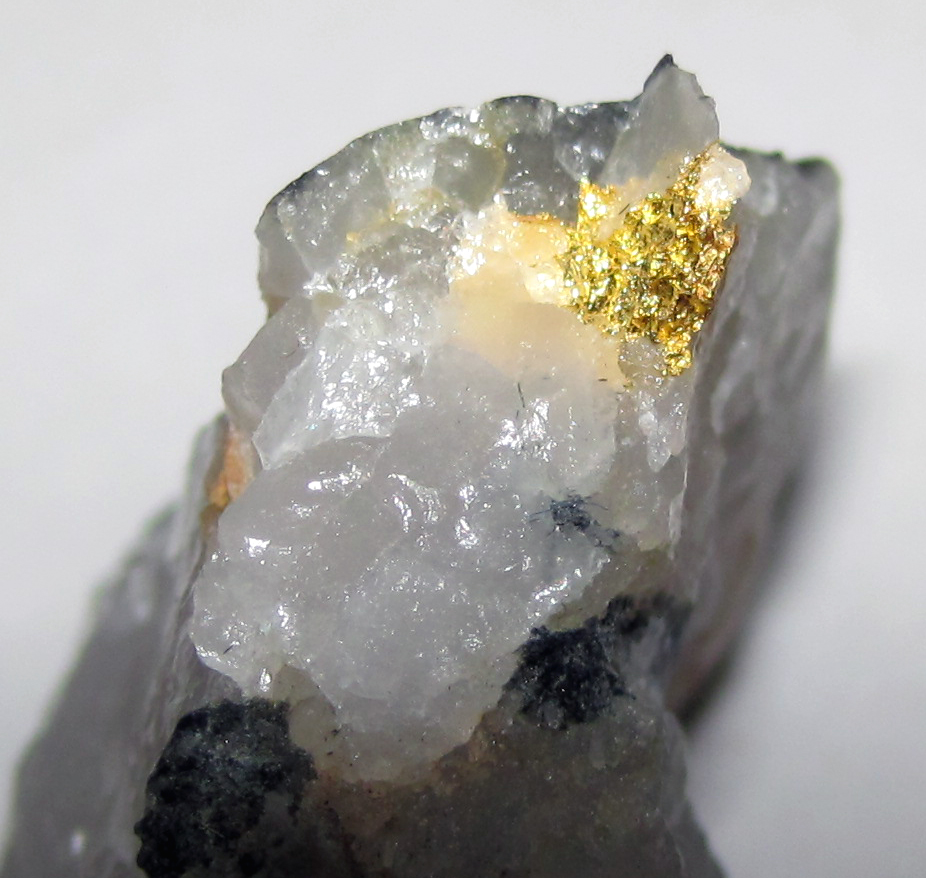

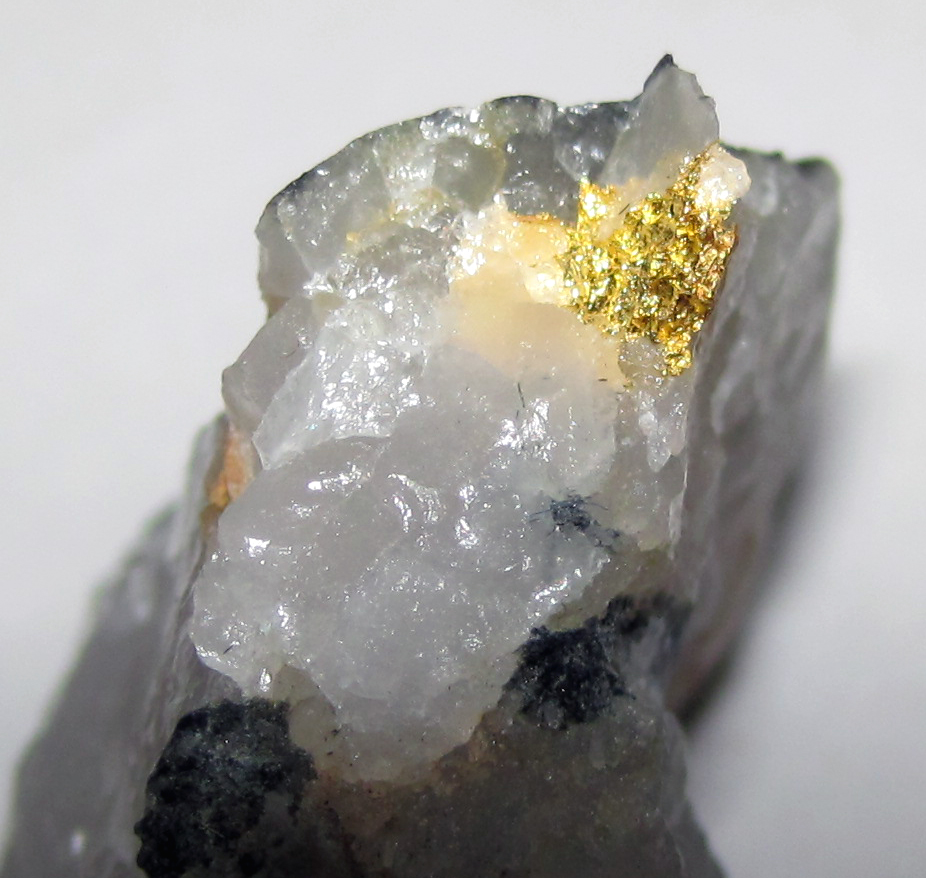

Gold in a piece of quartz from Manitoba (James St. John [CC BY], Wikimedia Commons)

Gold in a piece of quartz from Manitoba (James St. John [CC BY], Wikimedia Commons)

How does this align with my curriculum?

Learn about mines and mining in Canada

Mines and Mining

Mining is the process of removing minerals from the Earth. These minerals are usually found in rock. Rock containing minerals of interest we call ore.

Mining takes place at mines. There are two types of mines.

Image - Text Version

Shown is a colour photograph of a large, wide pit with a road and several trucks inside.

The camera is at the edge of the oval shaped pit. It is so large it takes up three quarters of the image. There is a thin strip of green grass near the horizon, and grey, cloudy sky above.

The sides of the pit are grey and shaped like steps or the tiered seats in a stadium. The widest tier is at the top. Each tier gets smaller until the flat bottom. A gravel road circles around the inside of the pit, from top to the bottom. Here, several large trucks appear tiny in the distance.

Image - Text Version

Shown is a colour aerial photograph of large structures near a rock cliff.

The image includes a very large section of the landscape. There is dense forest in the distance, on the horizon, and hazy blue sky above.

A two-lane gravel road curves from the forest, along the right edge, and bottom edge of the image. Two more roads run from a large parking lot to the bottom right corner. The parking lot is dotted with cars that look like tiny specks. The rest of the land between the roads and the cliff is covered with large, industrial structures. There are four wide, low rectangular buildings, two brown conical buildings with long grey pipes extending from them, two tall, thin, grey, windowless towers and two smaller green towers with green pipes extending from them.

Steps in Mining

Check out this interactive to learn about the steps in mining.

Mine Life Cycle

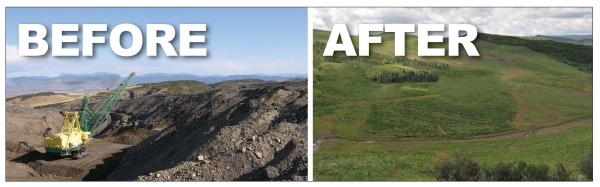

There are many stages in the life of a mine. These stages are called the mine life cycle. The stages include exploration, development, operation and closure/reclamation.

Mining Across Canada

Canada is a large country where many rocks contain valuable minerals. Mining takes place in 12 provinces and territories across the country. The only province without mining is Prince Edward Island. Canada is a global leader in mining. Canadian mines produce more than 60 different minerals and metals. The map below shows the location of mine types by province and territory.

Image - Text Version

Shown is a colour map of Canada labelled with letters.

The title "Mining in Canada" is in large black letters across the top of the illustration. In a column on the left side is a list of letters that represent metals. This reads: "A = Aluminum, C = Coal, Cu = Copper, Co = Cobalt, D = Diamond, G = Gold, I = Iron, L = Lead, M = Molybdenum, N = Nickel, P = Potash, Pa = Palladium, Pt = Platinum, S = Silver, T = Titanium, U = Uranium, Z = Zinc."

The water on the map is illustrated in blue. Canadian land is in green, and the land of other countries are in beige. Different shades of green are used to illustrate the different provinces and territories of Canada.

Starting on the top left, Yukon is labelled with G, Cu, and S in the centre of the territory. The Northwest Territories is labelled with D, just above Yellowknife. Nunavut has G and I on the mainland and on the islands.

Moving down to British Columbia, Cu, G, M, and C appear in the north, A on the coast, and Cu, G, M, L, Z, and C in the south. Alberta is only labelled with C, in the south. Saskatchewan is labelled with C and P in the south. Manitoba's labels are all in the northernhalf. These are N, Co, G, Cu and Z.

Most of Ontario's labels are also in the north. These are G, Pa, Pt, C, Z, and D. There are three more in the south, near the Great Lakes. These are N, Co, and Cu. Most of Québec's labels are across the centre. These are G, Co, D, Z, A, and T. There is also a T in the south, near Québec City, and an N at the northern tip of the province.

New Brunswick is labelled with Z, L, and P. Nova Scotia has a Z on the southern tip. In Newfoundland and Labrador, The northern part of Labrador is labelled with an N and the island of Newfoundland is labelled with G.

What is mined in Canada?

In Canada people mine for base metals, precision metals, diamonds and other minerals. Let’s look at some of these in more detail.

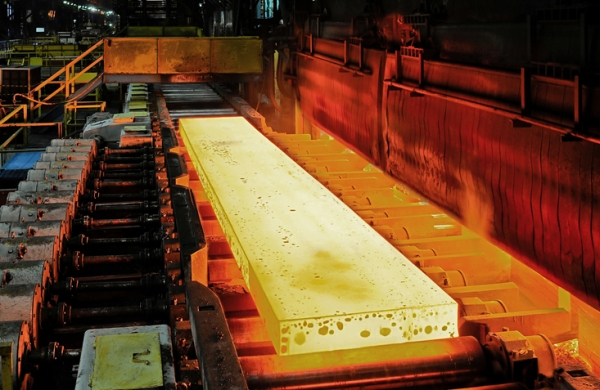

Base metals include metals such as iron, nickel, lead, zinc and copper. Base metal mines are located in many provinces and territories.

Image - Text Version

Shown is a colour photograph of a long, yellow, glowing rectangle on metal rollers.

The rectangle is a bright, golden yellow, like a flame. It stretches from the bottom edge of the image, towards a set of stairs in the distance. These illustrate that the rectangle is very large. The area underneath it glows orange, and lights up the surfaces around. In the background the inside of a large industrial building is visible.

Image - Text Version

Shown is a colour photograph of four large rolls of thick metal wire.

The wire is thick, round, reddish gold, and shiny. Each roll is coiled around a large, black, conical object at the centre. At the top of each one, one end of the wire is lifted up and around, out of the image.

Precious metals include such metals as gold and silver. Gold and silver mines are located in British Columbia, Northwest Territories, Saskatchewan, Manitoba, Ontario, Quebec, Nunavut, Yukon, Alberta as well as Newfoundland and Labrador.

Image - Text Version

Shown is a colour photograph of six bright gold pieces sitting on brown rock.

The gold is wet and gleams in the light. Each piece is shaped like a small pebble or piece of gravel. They are scattered in a small pool of water on a rough surface of beige and brown rock.

Image - Text Version

Shown is a colour photograph of a rough piece of grey, shiny material.

The top of the piece is flat, smooth, and dark grey. The edges are rough, as if they have been cut or broken. The texture inside has long, thin, vertical structures. These catch the light, shining in shades of pale, metallic grey.

Uranium is an element used to generate electricity in nuclear generating stations. It is mined only in Saskatchewan. Uranium is an element that gives off energy naturally. This makes it a good source of fuel. Uranium fuel is radioactive. That’s why it can generate electricity.

Image - Text Version

Shown is a colour, aerial photograph of a large industrial site in a vast forest dotted with lakes.

The beige ground of the site is in sharp contrast to the dark green trees and deep blue lakes around. A straight, beige road cuts through the forest on the top left. It leads to a series of square grey structures dug into the land. These are surrounded by the same beige as the road. In the centre, there are five bright green buildings and tall towers in a grid of roads. On the right is a large mound of dark grey soil or rock. In the foreground, a flattened mound of beige soil leads back down to the forest.

Image - Text Version

Shown is a colour, aerial photograph of a huge industrial site in a landscape of tundra and lakes.

The site looks like a tangled ball of grey string on the land. Several thin, snaking roads lead to a central grey mass. On the left of this mass are three perfectly round pits. They have been dug in concentric circles that get smaller as they get deeper. The bottoms of the pits are lost in shadow. Just above the top pit is a row of white buildings look tiny compared to the other structures.

In the background, green tundra dotted with lakes, stretches off to the horizon, hazy in the distance. There is one more round pit near the left edge of the image.

Learn More

Mining Week

This page of the Mining Matters website has activities, videos and posters about mining in Canada.

References

The Canadian Minerals and Metals Plan. (n.d.). Mining in Canada.

Natural Resources Canada. (n.d.). Mining & minerals.

Sandlos, J., & Keeling, A. (2009, April 7). Mining. The Canadian Encyclopedia.