Peter Rautapuro

Systems Engineer

MDS Aero Support Corporation

Learn About My Career

Peter Rautapuro is a Systems Engineer for MDS Aero Support Corporation.

I was born/grew up in: Toholampi, Finland

I now live in: Ottawa, Ontario, Canada

I completed my training/education at: Honours Co-op Chemical Engineering, University of Waterloo, Waterloo, Ontario. I also have 27 years as a professional Engineer.

Our company designs and constructs special buildings where airplane engines are tested to make sure they work properly. I am responsible for the complete design and implementation of the test systems. I make sure that everything that goes into the production of this building meets the contract specifications and are carried out properly. This includes everything from the types of wires, pipes, nuts and bolts being used, to the welding of different pieces of metals.

A multi-million dollar project such as designing and building a turbine engines test site has many different parts. Some parts need to be designed from scratch. Others may need to be modified. A building will have to be constructed to house the testing systems. This means that there are different engineering groups that need to work together. My job is to take a large technical contract and create smaller work packages for the different engineering teams who will be working on the project. I manage all the work packages and coordinate how they interact with each other.

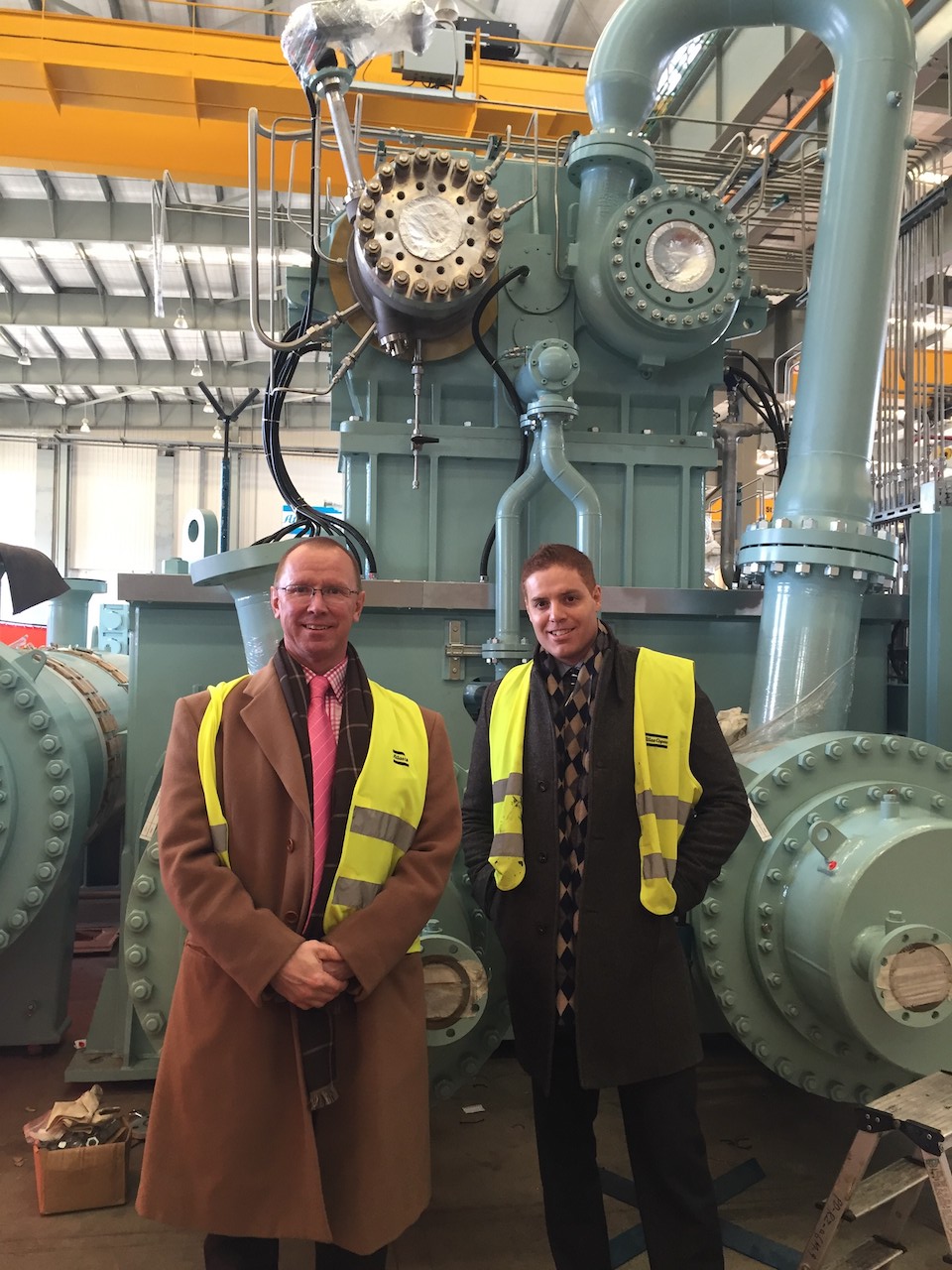

As the project moves from the design stage to purchasing of equipment and supplies, I work with our purchasing department to make sure the items we buy meet the quality requirements. I also make sure that equipment and supplies arrive where they are needed and on time.

Test systems are then shipped to the project site (often overseas) and installed. As the System Engineer, I have to make sure that all the things need to install the product is on hand. This includes making sure the correct people are available and that they have the proper tools and equipment they need to do their job. It also means that I have to make sure all permits are in place and we meet local regulations. After installation is complete, I oversee the final client sign off and ensure all documentation is completed.

All in all, I manage the entire technical specification for the project from beginning to end. This may take months to a number of years. It is very exciting to see it come together.

I got to where I am today by being the class nerd in high school, the one who always had his homework done and was member of the physics club and worked on computers. It gave me the skills to win a four-year scholarship allowing me to go to the University of Waterloo. I graduated as a Chemical Engineer yet spent most of my career doing mechanical, electrical, power, controls and instrumentation Engineering. I had chosen Chemical Engineering as I grew up in Sudbury and that was the logical choice if I wanted a job back with the mines in the refinery.

I have had to constantly reinvent myself as an Engineer as one segment of the market closed forcing me to learn new skills to enter a different market. When I lost my job in the wastewater industry, I studied up on controls and became and automation specialist 6 months later and then started designing conveyer belt lines and robotic control systems.

I bore easily. New challenges and problems excite me. I love designing something completely new, with ever-increasing sizes of facilities due to the higher thrust of high bypass aviation engines, the job never ceases to impress me. Though what I enjoy most is the act that this is an international career where I spend a lot of my meetings throughout the world. I meet other engineers who have grown up in completely different cultures. Seeing engineering through their eyes and what aspects of the design are important has changed how past western thinking.

The challenge of making one-of-a-kind designs to accommodate the leading-edge aerospace engine technology is the fact that we are designing the test facilities to test gas turbine engines (airplane engines or industrial engines) before the public even knows that this new technology exists. The world’s leading engine manufacturers have a new engine to test, so they often need a brand-new building to make sure their engine is tested properly for performance, safety, and a number of other requirements. This testing directly affects peoples’ lives because some of these engines propel the airplanes they fly on daily. Our company gives the manufacturers the means to ensure the engines are safe and reliable before they go into production or before they are put back on a plane after maintenance.

My career matters in that I am the glue that puts the whole thing together. Our company has brilliant minds on hand to design the facility and test systems, but someone has to manage the technical part of the project as a whole. I am the person that helps coordinate multi-disciplinary activities to pull it all together.

For fun I race and coach people for the Ironman Triathlon. In 2018 I represented Finland at the Kona Ironman Triathlon World Championships. Thus far, I have completed 20 Ironman Competitions, 100s of shorter triathlons, and marathon races in running, biking, skiing, and skating. I also do woodworking in my spare time. I am a husband and father of two.

The best way to choose a career is to do research. Find out all that there is about the career that interests you to find out if that is the correct choice for you. I was fortunate to be in a Co-op program in university. Here I was able to experience 4-month terms for different engineering jobs in different areas. This gave me the insight to know I wanted to be in process engineering and react to daily issues over a research based engineering position. Investing 5 years into a program and perhaps a lifetime into a specialty should be done on an informed basis.

What I do at work

Our company designs and constructs special buildings where airplane engines are tested to make sure they work properly. I am responsible for the complete design and implementation of the test systems. I make sure that everything that goes into the production of this building meets the contract specifications and are carried out properly. This includes everything from the types of wires, pipes, nuts and bolts being used, to the welding of different pieces of metals.

A multi-million dollar project such as designing and building a turbine engines test site has many different parts. Some parts need to be designed from scratch. Others may need to be modified. A building will have to be constructed to house the testing systems. This means that there are different engineering groups that need to work together. My job is to take a large technical contract and create smaller work packages for the different engineering teams who will be working on the project. I manage all the work packages and coordinate how they interact with each other.

As the project moves from the design stage to purchasing of equipment and supplies, I work with our purchasing department to make sure the items we buy meet the quality requirements. I also make sure that equipment and supplies arrive where they are needed and on time.

Test systems are then shipped to the project site (often overseas) and installed. As the System Engineer, I have to make sure that all the things need to install the product is on hand. This includes making sure the correct people are available and that they have the proper tools and equipment they need to do their job. It also means that I have to make sure all permits are in place and we meet local regulations. After installation is complete, I oversee the final client sign off and ensure all documentation is completed.

All in all, I manage the entire technical specification for the project from beginning to end. This may take months to a number of years. It is very exciting to see it come together.

My career path is

I got to where I am today by being the class nerd in high school, the one who always had his homework done and was member of the physics club and worked on computers. It gave me the skills to win a four-year scholarship allowing me to go to the University of Waterloo. I graduated as a Chemical Engineer yet spent most of my career doing mechanical, electrical, power, controls and instrumentation Engineering. I had chosen Chemical Engineering as I grew up in Sudbury and that was the logical choice if I wanted a job back with the mines in the refinery.

I have had to constantly reinvent myself as an Engineer as one segment of the market closed forcing me to learn new skills to enter a different market. When I lost my job in the wastewater industry, I studied up on controls and became and automation specialist 6 months later and then started designing conveyer belt lines and robotic control systems.

I am motivated by

I bore easily. New challenges and problems excite me. I love designing something completely new, with ever-increasing sizes of facilities due to the higher thrust of high bypass aviation engines, the job never ceases to impress me. Though what I enjoy most is the act that this is an international career where I spend a lot of my meetings throughout the world. I meet other engineers who have grown up in completely different cultures. Seeing engineering through their eyes and what aspects of the design are important has changed how past western thinking.

How I affect peoples’ lives

The challenge of making one-of-a-kind designs to accommodate the leading-edge aerospace engine technology is the fact that we are designing the test facilities to test gas turbine engines (airplane engines or industrial engines) before the public even knows that this new technology exists. The world’s leading engine manufacturers have a new engine to test, so they often need a brand-new building to make sure their engine is tested properly for performance, safety, and a number of other requirements. This testing directly affects peoples’ lives because some of these engines propel the airplanes they fly on daily. Our company gives the manufacturers the means to ensure the engines are safe and reliable before they go into production or before they are put back on a plane after maintenance.

My career matters in that I am the glue that puts the whole thing together. Our company has brilliant minds on hand to design the facility and test systems, but someone has to manage the technical part of the project as a whole. I am the person that helps coordinate multi-disciplinary activities to pull it all together.

Outside of work I

For fun I race and coach people for the Ironman Triathlon. In 2018 I represented Finland at the Kona Ironman Triathlon World Championships. Thus far, I have completed 20 Ironman Competitions, 100s of shorter triathlons, and marathon races in running, biking, skiing, and skating. I also do woodworking in my spare time. I am a husband and father of two.

My advice to others

The best way to choose a career is to do research. Find out all that there is about the career that interests you to find out if that is the correct choice for you. I was fortunate to be in a Co-op program in university. Here I was able to experience 4-month terms for different engineering jobs in different areas. This gave me the insight to know I wanted to be in process engineering and react to daily issues over a research based engineering position. Investing 5 years into a program and perhaps a lifetime into a specialty should be done on an informed basis.

When I was a student I enjoyed:

- Computer Science

- Math

- Physical Education / Health

- Science

When I was a student, I would describe myself as someone who:

- Liked helping people

- Organized activities for my friends

- Played on a sports team

- Was motivated by success

- Wanted to be in charge

- Liked being given free range to eplore my ideas

- Was really creative

- Felt great satisfaction in getting good grades

- Liked to take things apart to see how they worked

Related Topics

Explore More Career Profiles

-

Brianna Lummerding

Career Profiles

Agronomic Innovation Manager

I look after all things related to soil management for a group of retailers. -

Li Tan (he/him)

Career Profiles

Molecular Lead

I coordinate the day-to-day operations in the DNA Extraction Lab. -

Tyler Morhart (video)

Career Profiles

Scientist, Beamline Responsible - SyLMAND

I am responsible for the SyLMAND beamline at the Canadian Light Source synchrotron facility. -

Li Tan (Video)

Career Profiles

Molecular Lead

I coordinate the day-to-day operations in the DNA Extraction Lab. -

Rashell Featherstone (she/her)

Career Profiles

Senior Program Associate

I coordinate projects for the development of new products at STEMCELL. -

Kira Hoffman (she/her)

Career Profiles

Postdoctoral Researcher/Fire Ecologist

I am a researcher at both a university and a not-for profit organization where I am gaining experience to become a senior researcher. -

Zoë Ehlert (Video)

Career Profiles

Manager, Marker Assisted Breeding

I lead a team that develops canola crops by breeding plants with traits we are looking for. -

Zoë Ehlert

Career Profiles

Manager, Marker Assisted Breeding

I lead a team that develops canola crops by breeding plants with traits we are looking for. -

Jennifer Baltzer (she/her)

Career Profiles

Professor and Canada Research Chair in Forests and Global Change

I work at a university, teaching students and conducting research on the impact of climate change on forests in Canada and around the world. -

Caitlyn Lyons (she/her)

Career Profiles

Ph.D. Candidate

I am working towards my PhD and studying the forests in the Northwest Territories. -

Joann Whalen

Career Profiles

Professor at the Faculty of Agricultural and Environmental Sciences,

I teach advanced courses on how to manage soils to produce healthy, nutritious food and maintain healthy ecosystem functions.