What is Welding?

Welding trainee (BartCo, iStockphoto)

Welding trainee (BartCo, iStockphoto)

How does this align with my curriculum?

Learn about the science involved in combining two metals by welding.

Image - Text Version

Shown is a colour photograph of a car going through an assembly line. The bare metal body of the car takes up much of the frame. The car does not have a trunk door, so the entire rear section of the car interior is visible. A robotic welding arm creates a shower of sparks from the trunk section on the right passenger side.

History of Welding

Image - Text Version

Shown is a colour photograph of hot molten bronze being poured into a mold. The mold looks a bit like a brick with a cylindrical hole down the centre. A red hot cup-shaped container holds the liquid metal. It is being held by a pair of sturdy metal tongs. The two sides of the mold are held together by two sturdy sticks which are tied together with leather strapping. The bottom of the mold is in a barrel containing sand.

Did you know?

Bronze is an alloy made of the chemical elements copper and tin.

Image - Text Version

Shown is a colour photograph of the Iron Pillar of Delhi. The 7.3 metre iron pillar is a dark rusty grey colour. Most of the pillar is cylindrical and unadorned, but the top metre has bands of decorative elements. Pillar stands alone in an empty courtyard. A small decorative pale yellow metal fence surrounds the decorative base of the pillar.

Image - Text Version

Shown is a colour photograph of a person arc welding. The person is wearing dark grey coveralls and an elaborately decorated welding face shield. Blue sparks and white light are coming off the piece of metal where the electrode touches the base metal.

These techniques were further improved throughout the 20th century. Even more recent welding techniques involve magnetic pulses, lasers, x-rays and automated robots.

Chemistry of Welding

Think about how you would attach two pieces of paper together. You might use tape, staples or glue. Even after attaching them, the paper is still paper and the tape is still tape, even if the paper-tape seems to be one thing. But what if you wanted to attach two metal bars together. Would you use tape or glue now? Probably not. Especially if you did not want the metal bars to come apart! This is where welding comes in. Welding is not like glue. It combines two pieces of metal into one. This makes for a very strong bond between pieces. But how does it work? We can use chemistry to help us understand the process.

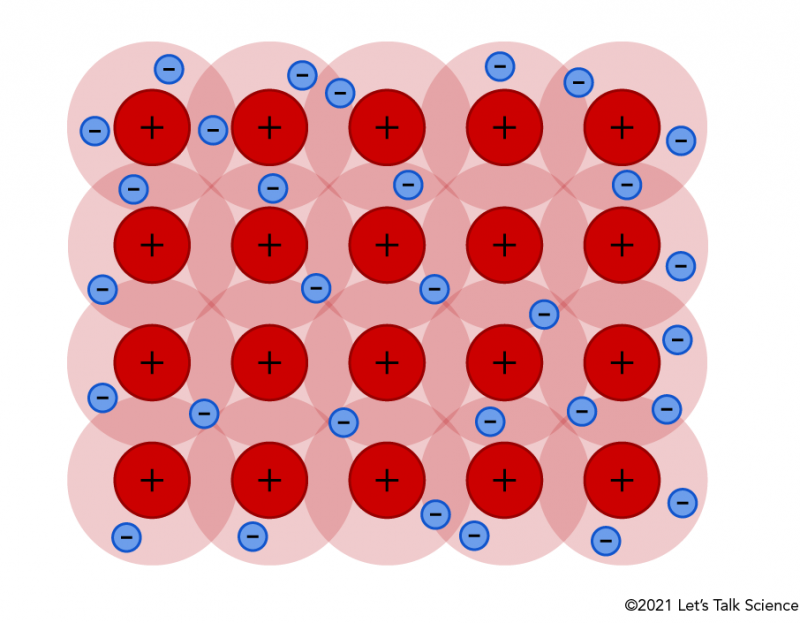

Image - Text Version

Shown is a colour illustration showing the arrangement of atomic nuclei and electrons in a metallic bond. The nuclei are represented by red circles with black plus signs on them to indicate their positive charge. There are twenty nuclei arranged in four rows and five columns.

The electrons are represented by blue circles with black minus signs on them to indicate their negative charge. Encircling each nuclei is a translucent pink area. This represents the area where the electrons can be found. The blue electrons are scattered throughout this pink region.

These strong bonds explain many of the properties of metals. Metals generally have high melting points. They are also malleable and ductile. This means that they can be stretched and formed into different shapes without breaking. We can weld metal because of these properties.

Did you know?

Tungsten has the highest melting point of all pure metals. Its melting point is 3422 °C.

Image - Text Version

Shown is a photograph of a grilled cheese sandwich. The slices of bread are toasted, and slightly burned. The sandwich is cut in half diagonally. Gooey melted white and orange cheese is oozing out of the sandwich and onto the surface below.

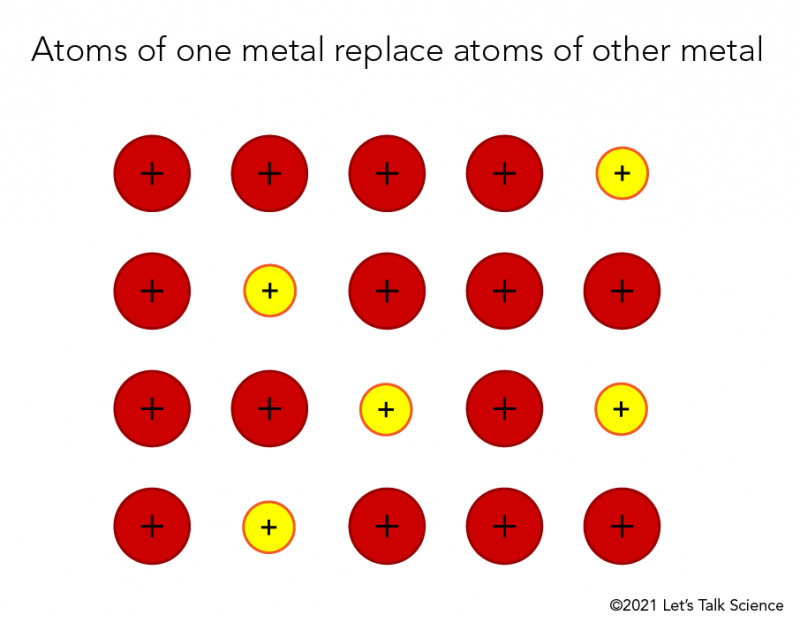

Image - Text Version

Shown is a colour illustration showing the arrangement of atomic nuclei when two metals are melted together. The nuclei of one metal are represented by red circles with black plus signs on them to indicate their positive charge. The nuclei of the other metal are represented by yellow circles with black plus signs on them to indicate their positive charge.

There are twenty nuclei arranged in a pattern with four rows and five columns. There are 15 red nuclei and five yellow nuclei. The yellow nuclei are randomly located in the pattern.

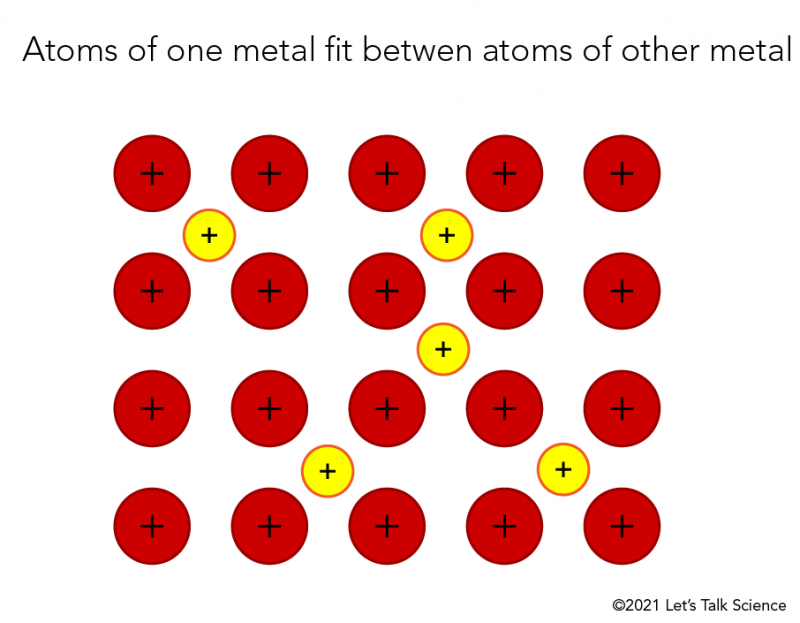

Image - Text Version

Shown is a colour illustration showing the arrangement of atomic nuclei when two metals are melted together. The nuclei of one metal are represented by red circles with black plus signs on them to indicate their positive charge. The nuclei of the other metal are represented by yellow circles with black plus signs on them to indicate their positive charge.

There are twenty red nuclei arranged in a pattern with four rows and five columns. There are five yellow nuclei randomly located in the spaces between the red nuclei.

Types of Welding

To get metals to melt, you need high temperatures. Generating a high temperature can come from using energy sources such as:

- Electricity

- Gas

- Lasers

- Sound (ultrasound)

- Friction

Arc Welding

Image - Text Version

Shown is a colour photograph of a person arc welding a long metal pipe. In the foreground is the welder. The person is wearing bright red coveralls, a black welding face shield and bright blue welding gloves. A bright light is coming off the pipe where the electrode touches it. Bluish smoke is swirling into the air above the welding area. In the background is a blurred out workshop.

Image - Text Version

Shown is a colour illustration of a welder at work.

On the left of the image is the power source. It is a rectangular shape with knobs and a display.

Connected to it are two wires. The upper wire has a red circle with a plus sign. This indicates that it is the positive end of the power source. The lower wire has a blue circle with a minus sign. This indicates that it is the negative end of the power source. The positive wire is identified as the welding cable. This is connected to an electrode holder in the welder's hand. The Electrode holder is connected perpendicularly to the end of an electrode. The electrode is grey with a red outline. The red part is identified as the flux coating. The negative wire is identified as the ground cable. It is connected to a large ground clamp that is clamped onto a piece of pipe.

The welder is located in the centre of the image. is in full safety gear including sturdy grey boots, blue welding coveralls, knee pads, a leather apron, long yellow welding gloves, an orange welding hood and a dark grey protective face shield.

On the right side of the image is a piece of jointed pipe with two right angle bends in it. The ground clamp is connected to this pipe. The pipe is identified as being made of ground metal. This is the same type of metal as in the electrode. There is a large black crack in the pipe. At the top of the crack is a yellow and orange starburst. This is where the electrode and base metal meet to form an electric current which heats the metal at the junction site. Surrounding this site is a pale blue halo which represents the gas shield that is given off when the flux is heated. Above the welding area is a bumpy grey part which is the previously welded metal, sealing up the crack.

It is very important while arc welding that the surfaces being welded are very clean. This is to prevent things like rust and corrosion from weakening the joint. To make and keep the surfaces clean, welders use a shielding gas. The shielding gas is a bit like a “force field” that protects the welding area from being contaminated by stuff in the air. So, where does this gas come from?

If you check out the image above, you will notice something called “flux coating” on the outside of the electrode. When the flux is heated up, it produces gases and also forms a slag that covers and protects the molten metal in the weld. It can also act as an oxygen barrier, preventing the surface from reacting with oxygen in the air.

Metal inert gas (MIG) welding gets its shield gas in a slightly different way. Along with the wire electrode is a tube that sends out the shield gas from a high-pressure gas cylinder, instead of the gas coming from flux.

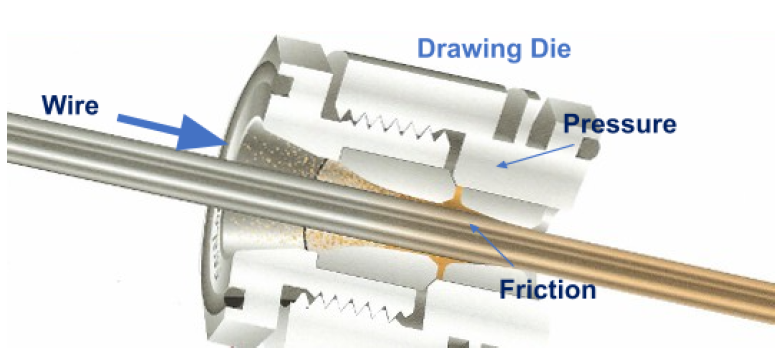

Not just any wire is used in MIG welding. The production process of this wire makes MIG welding possible. Wire is made using a process called Wiredrawing. In this process, metal is pulled through the holes of a die where it is strained into the correct size.

As part of the welding process, the wire travels from spools through as much as 5 metres (15 feet) of tubing to reach the welder. To make sure that the wire does not get stuck in the tube, a lubricant is used during the drawing process. The lubricant leaves a residual film on the surface of the wire. Lubricants help the wire feed through the tube smoothly and easily. Since there is also air in the tube, the film of lubricant must also protect the wire from being exposed to oxygen.

But not just any lubricant will do. Welding wire requires special lubricants. These lubricants leave a residue that helps with the melting process and improves the stability of the arc. However, these lubricants are often toxic and harmful to people and the environment.

Blachford supplies wire drawing lubricants and surface treatment products to the global welding wire industry. Blachford has developed a new safe and effective lubricant to solve this problem. Their new water-based formula contains a soap for making the wire slippery, compounds for corrosion protection, special additives, and emulsifiers for combining the two things together.

We may think about welding or welding wire rarely. However, these processes are central to many of the technologies that we rely on everyday. Understanding these techniques can help us build safer and better functioning technology.

Let’s Talk Science appreciates the work and contributions of H.L Blachford Ltd. in the development of this Backgrounder.

About H.L Blachford Ltd.

H.L Blachford Ltd was founded in Montreal in 1921 by Henry Lloyd Blachford and has grown its operations to include manufacturing sites in the USA, Canada, and the UK. Blachford manufactures stearate based products for a variety of industries including rubber, tire, powdered metal, plastics, PVC, food, wire drawing and metal working. Blachford is also a leading manufacturer of noise and vibration control technology, heavy duty rubber mats and headliners for the transportation and agricultural equipment industries.

Learn More

Career Profile: Ethan Martin

Watch this video of Ethan Martin to learn more about what it’s like to pursue a career as a welder.

Why Wires

Read this article to learn more about how wires are produced and used.

Career Profile: Rebecca Smith

Read Rebecca Smith’s career profile to learn more about what it’s like to pursue a career as a welder.

Iron Pillar of Delhi: Solving the Mystery (2020)

This article, from Live History India, explores this famous, and mysterious, landmark.

References

BBC Bitesize (n.d.) Metals and Alloys - AQA. Retrieved from https://www.bbc.co.uk/bitesize/guides/ztgy6yc/revision/1

Dekker, C. (Jan 7, 2022). When Was Welding Invented? Water Welders. Retrieved from https://waterwelders.com/when-was-welding-invented/

Lincoln Tech (Jun 3, 2021). 4 Popular Types of Welding Procedures. Retrieved from https://www.lincolntech.edu/news/skilled-trades/welding-technology/types-of-welding-procedures

Longevity (Feb 8, 2019). Internal Structures of Metal Used in Welding. Retrieved from https://www.longevity-inc.com/welding-articles/post/internal-structures-of-metals-used-in-welding-industry

Pace, G. (Apr 28, 2019). CWI Course Module 8 - Welding Chemistry [Video]. YouTube. https://www.youtube.com/watch?v=kmbq2E8SOcw

Vyas, K. (Feb 6, 2021). Types of Welding: Applications, Advantages, and Disadvantages. Interesting Engineering. Retrieved from https://interestingengineering.com/types-of-welding-their-applications-advantages-and-disadvantages

Young, P. (Aug 15, 2021). What is MIG Welding - Understanding It Thoroughly. Welding Headquarters. Retrieved from https://weldingheadquarters.com/what-is-mig-welding/